To make woven fabrics yarns are – To make woven fabrics, yarns are the fundamental building blocks that determine the fabric’s appearance, texture, and performance. Understanding the types of yarns and the weaving process is essential for creating high-quality and visually appealing woven fabrics.

This comprehensive guide explores the intricacies of yarn characteristics, weaving techniques, and design considerations for woven fabrics. From plain weaves to intricate jacquards, we delve into the factors that influence the aesthetic and functional properties of these versatile textiles.

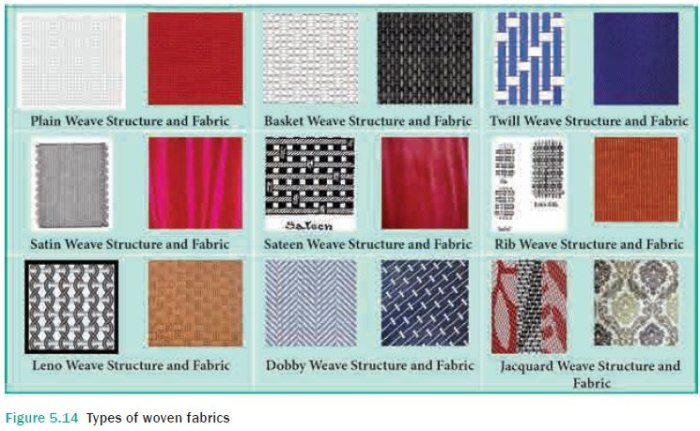

Types of Woven Fabrics

Woven fabrics are classified based on their weave patterns, which determine the appearance, texture, and durability of the fabric. The three primary weave patterns are plain weave, twill weave, and satin weave.

Plain Weave

Plain weave is the most basic and common weave pattern. It involves alternating one weft yarn over and under one warp yarn, creating a simple grid-like pattern. Fabrics woven with a plain weave are typically smooth, durable, and have a balanced appearance.

Examples include calico, muslin, and shirting.

Twill Weave

Twill weave creates a diagonal pattern on the fabric surface. It involves alternating weft yarns over two or more warp yarns, then under one or more warp yarns. This creates a distinct diagonal rib or twill line. Twill fabrics are known for their durability, wrinkle resistance, and drape.

Examples include denim, gabardine, and herringbone.

Satin Weave

Satin weave produces a smooth, lustrous fabric with a high sheen. It involves floating one weft yarn over multiple warp yarns, then under one warp yarn. This creates a long, unbroken surface on one side of the fabric, resulting in a luxurious appearance.

Satin fabrics are typically delicate and prone to snagging. Examples include silk satin, charmeuse, and duchesse satin.

Yarn Characteristics for Woven Fabrics

Yarn characteristics play a crucial role in determining the appearance, texture, and performance of woven fabrics. The choice of yarn type, yarn count, and twist significantly influences the fabric’s properties, such as drape, strength, and durability.

Fiber Type

The type of fiber used in the yarn determines the inherent properties of the fabric. Natural fibers, such as cotton, wool, and silk, impart different characteristics compared to synthetic fibers, such as polyester, nylon, and acrylic.

- Natural fibers offer breathability, comfort, and a natural aesthetic.

- Synthetic fibers provide enhanced durability, wrinkle resistance, and moisture-wicking properties.

Yarn Count

Yarn count refers to the thickness or fineness of the yarn. It is measured in units of “count” or “tex.” Higher yarn counts indicate finer yarns, while lower yarn counts indicate coarser yarns.

- Finer yarns produce smoother, more delicate fabrics with a higher thread count.

- Coarser yarns create fabrics with a more textured, rugged appearance.

Twist

Twist refers to the number of turns per unit length applied to the yarn during spinning. Twist affects the strength, elasticity, and appearance of the fabric.

- High twist yarns produce stronger, more elastic fabrics with a firmer handle.

- Low twist yarns result in softer, more pliable fabrics with a more relaxed drape.

Weaving Process for Woven Fabrics

The weaving process transforms prepared yarns into woven fabrics, involving several key steps:

Yarn Preparation:Before weaving, yarns are subjected to preparatory processes like warping and sizing to enhance their strength and weaving efficiency.

Warping:Yarns intended for the fabric’s lengthwise direction (warp) are arranged in parallel on a warping frame, creating a warp sheet.

Sizing:Warp yarns are coated with a sizing agent, typically starch or synthetic polymers, to improve their strength, reduce friction during weaving, and prevent breakage.

Loom and Its Components

The loom is the primary equipment used in weaving, consisting of several essential components:

- Warp Beam:Holds the warp sheet under tension.

- Cloth Beam:Receives the woven fabric.

- Heddle Frames:Guide the warp yarns, separating them into two layers (sheds) for weft insertion.

- Shuttle or Projectile:Carries the weft yarn across the warp.

- Reed:Separates the warp yarns to create the desired fabric width.

- Beat-up Mechanism:Presses the weft yarn against the previously woven fabric.

Weaving

The weaving process begins with the creation of the shed, where the heddle frames lift specific warp yarns to create an opening for the weft yarn. The shuttle or projectile then inserts the weft yarn across the warp, and the beat-up mechanism presses it into place.

This process repeats, alternating the sheds and inserting weft yarns until the desired fabric length is achieved.

Fabric Finishing, To make woven fabrics yarns are

Once woven, the fabric undergoes finishing processes to enhance its appearance, properties, and durability:

- Desizing:Removes the sizing agent applied during preparation.

- Scouring:Cleans the fabric to remove impurities.

- Bleaching:Whitens the fabric or removes unwanted colors.

- Dyeing:Adds color to the fabric.

- Finishing Treatments:Imparts specific properties like wrinkle resistance, water repellency, or flame retardancy.

Design Considerations for Woven Fabrics: To Make Woven Fabrics Yarns Are

The design of woven fabrics plays a crucial role in determining their aesthetic appeal, functionality, and suitability for specific applications. When designing woven fabrics, several factors must be taken into account, including pattern, color, and texture.

Pattern refers to the arrangement of yarns in the fabric. Different weaving techniques can create various patterns, such as plain weave, twill weave, and satin weave. The choice of pattern influences the fabric’s appearance and texture, as well as its drape and handle.

Color is another important design consideration. The color of the fabric can affect its overall appearance, mood, and style. Designers may choose to use a single color, multiple colors, or even create intricate patterns using different colored yarns.

Texture refers to the surface feel of the fabric. It can be smooth, rough, soft, or coarse, depending on the type of yarns used and the weaving technique employed. Texture can significantly impact the fabric’s visual appeal and its suitability for different applications.

Color and Pattern Considerations

The choice of color and pattern in woven fabrics can significantly impact their aesthetic appeal. Bright colors and bold patterns can create eye-catching and vibrant fabrics, while more subtle colors and understated patterns can result in sophisticated and elegant fabrics.

The color and pattern of a fabric can also influence its mood and style. For example, warm colors such as red, orange, and yellow can create a cheerful and inviting atmosphere, while cool colors such as blue, green, and purple can evoke a sense of calm and serenity.

Texture Considerations

The texture of a woven fabric can affect its visual appeal and its suitability for different applications. Smooth fabrics can create a sleek and sophisticated look, while rough fabrics can add a sense of texture and interest.

The texture of a fabric can also impact its functionality. For example, fabrics with a rough texture can be more durable and resistant to wear and tear, while fabrics with a smooth texture can be more comfortable to wear.

Applications of Woven Fabrics

Woven fabrics find extensive applications in various industries due to their unique properties and versatility. Their exceptional strength, durability, and aesthetic appeal make them ideal for a wide range of products.

In the apparel industry, woven fabrics are used to create a diverse range of garments, including shirts, pants, dresses, suits, and jackets. Their breathability, comfort, and drape make them suitable for both casual and formal wear.

Home Furnishings

Woven fabrics play a significant role in home furnishings, adding comfort, style, and functionality to living spaces. They are used in curtains, upholstery, carpets, and bedding, providing warmth, texture, and visual appeal.

Industrial Applications

Woven fabrics have numerous industrial applications, including filtration, conveyor belts, and protective clothing. Their strength and durability make them suitable for demanding environments, where they can withstand harsh conditions and provide protection.

Medical Applications

In the medical field, woven fabrics are used in surgical gowns, bandages, and medical devices. Their sterility, absorbency, and breathability make them essential for maintaining hygiene and promoting healing.

Technical Applications

Woven fabrics are employed in various technical applications, such as sails, parachutes, and airbags. Their lightweight, high strength-to-weight ratio, and resistance to tearing make them ideal for these specialized purposes.

Advanced Techniques in Woven Fabric Production

In recent years, the woven fabric industry has witnessed significant advancements in technology and innovation. These advanced techniques have enabled manufacturers to create novel and sophisticated fabrics with enhanced properties and design possibilities.

One notable innovation is 3D weaving, which involves weaving yarns in multiple directions to create three-dimensional structures. This technique allows for the production of complex and intricate fabrics with unique textures, shapes, and properties. 3D woven fabrics offer improved strength, durability, and breathability, making them suitable for various applications, including medical textiles, protective clothing, and architectural structures.

Digital Printing

Digital printing is another transformative technology that has revolutionized the woven fabric industry. Unlike traditional printing methods that rely on screens or rollers, digital printing uses computer-controlled inkjet technology to apply designs and patterns directly onto the fabric. This technique offers unparalleled precision, color accuracy, and the ability to create intricate and detailed designs.

Digital printing enables the production of custom fabrics with personalized designs, short-run production, and rapid prototyping. It has opened up new possibilities for designers and manufacturers, allowing them to explore innovative and expressive fabric designs.

FAQ Overview

What are the different types of yarn used in woven fabrics?

Yarns used in woven fabrics vary based on fiber type (natural or synthetic), yarn count (thickness), and twist (direction and amount of twisting). Different combinations of these properties create yarns with unique characteristics that influence the appearance and performance of the fabric.

How does the weaving process affect the fabric’s properties?

The weaving process, including the weave pattern (plain, twill, satin, etc.), loom type, and tension, plays a crucial role in determining the fabric’s texture, drape, and durability. Different weave patterns create distinct visual effects and influence the fabric’s strength and flexibility.

What factors should be considered when designing woven fabrics?

Design considerations for woven fabrics include pattern, color, texture, and intended application. Designers must carefully select yarns, weave patterns, and finishing treatments to achieve the desired aesthetic and functional properties for specific products or industries.